Colour is the most important factor when we select paint for decorative purposes. The ingredient in paint, that is responsible for colour are pigments. Pigments are the only solid phase material in most of the paint formulation, which others are in liquid form.

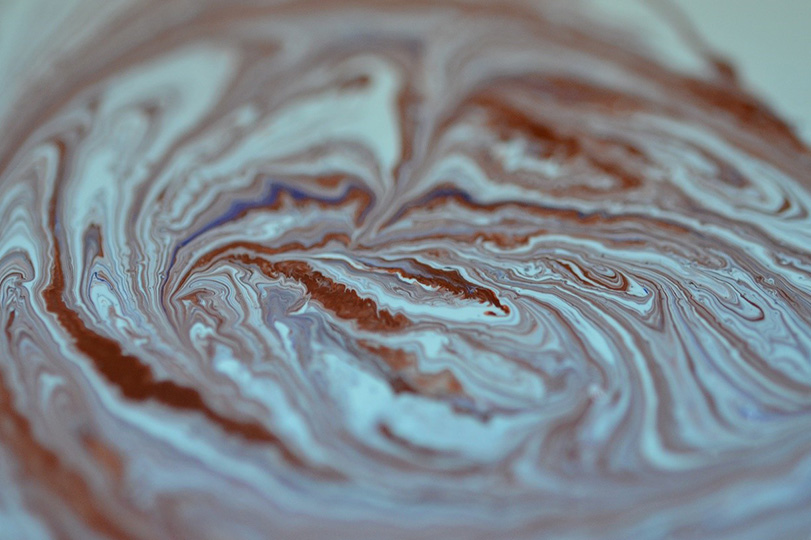

Pigments need to be evenly distributed in coating in order to achieve a bright, clean and attractive colour. In order to do that, these pigments have to been stabilizes in small particles when the paint is in the can for long period.

High molecular weight dispersants are the best choice to perform this task and they are the most efficient chemical compound to achieve the desired performance.

AFCONA additives produce wide range of high molecular weight dispersing agents, ranging from Polyurethane based to Polyacrylic based which are suitable for all solvent-based coatings and industrial water-based systems. Dispersants are one of our most outstanding specialties in all of our additives range.

In the history of pigments, if we look back 50-60 years, most pigments are metal oxides, which we dig from the ground. Thus at that time, wetting and dispersing agent are created to improve properties of paint.

Until today, these wetting and dispersing agent are still widely use for primers and coatings function as protection for substrates rather than for decoration and as wetting dispersing agent for easy stabilization of pigments. They currently categorized under conventional wetting and dispersing agents.

AFCONA additives produce wide range of conventional wetting and dispersing agents to suite different needs of customers. All these products based on formation of polymer salts provide the wetting and dispersing properties. In addition, they promote anti-gravity effect for anti-settling effect.

Download Technical Literature

Download Technical Literature

苏公网安备 32068402000156号

苏公网安备 32068402000156号